At the heart of internal combustion engines, the piston and crankshaft assembly bears the brunt of high loads, enduring intricate cycles of bending and torsion stresses. Recognizing the complexity of this crucial component, our work embarks on a parametric exploration to understand the performance intricacies of the assembly.

The Foundation of the Study:

Our focus is on a 3-D model of the assembly, leveraging symmetry wherever possible to streamline analyses. Delving into the nuances of the crank throw, we scrutinize governing parameters such as journal diameters, crankpin dimensions, and web thickness. These parameters play a pivotal role in shaping the performance and reliability of the piston and crankshaft assemblies.

Objectives of the study:

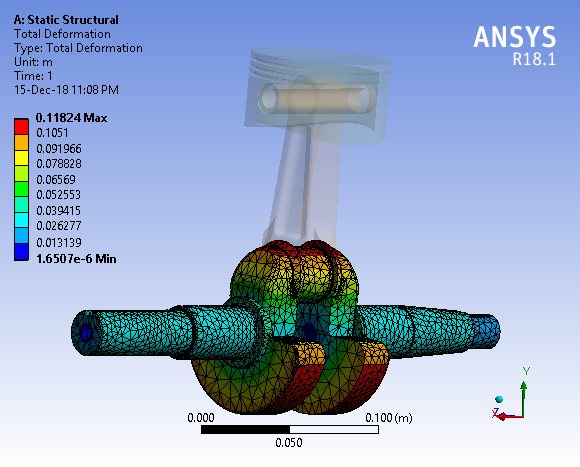

The primary objective is to unravel the performance dynamics of the piston and crankshaft assemblies. Employing advanced tools like CATIA, ANSYS, and MINITAB, our approach combines finite element analysis with analysis of variance (ANOVA). ANSYS provides a detailed look into the assembly’s behavior, and MINITAB transforms these results into a robust ANOVA model for predicting performance outcomes.

Methodology:

In a bid to navigate the complexities efficiently, we acknowledge the time constraints of full assembly simulations in everyday engineering tasks. However, our focus on Total Deformation, Equivalent Stress, Equivalent Elastic Strain, and Strain Energy reveals a silver lining. Simplified models prove to be adept at successfully predicting these critical parameters, offering a practical solution for engineers seeking precision without sacrificing efficiency.

Discoveries and Implications:

The exploration into the performance of the piston & crankshaft assembly yields valuable insights. While the comprehensive simulation of the entire assembly process may be time-consuming, the ability to predict key parameters with simplified models represents a significant breakthrough. Total Deformation, Equivalent Stress, Equivalent Elastic Strain, and Strain Energy emerge as focal points, providing a nuanced understanding of the assembly’s behavior.

Conclusion:

This study marks a pivotal contribution to the understanding of the piston & crankshaft assembly’s parametric performance. The integration of CATIA, ANSYS, and MINITAB enables a holistic exploration, laying the groundwork for informed design decisions. As we strive for precision in the realm of internal combustion engines, this research equips engineers with the tools to enhance performance, durability, and reliability in the intricate dance of the piston & crankshaft assembly.