Bush bearings play a pivotal role in the efficient operation of rotating equipment, such as turbines, generators, blowers, rolling mills, and various industrial machines. These components are critical for minimizing friction, supporting large loads, and ensuring the accurate alignment of the axis of rotation. The significance of bush bearings cannot be overstated, considering that approximately 70% of mechanical component failures can be attributed to tribological challenges, leading to substantial energy wastage.

The history of bush bearings is extensive, and their continued use in a diverse array of applications underscores their enduring importance. Whenever a system requires either low-friction torque or high-speed rotation, one or more bush bearings are typically incorporated. The versatility of these bearings makes them indispensable in machines where reliability and load capacity are paramount.

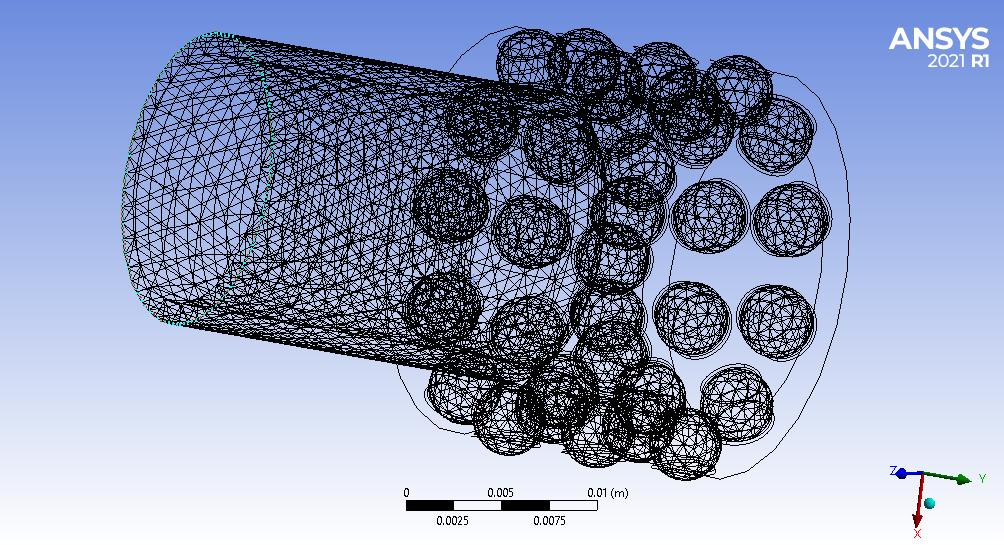

To comprehend and enhance the functional capabilities of bush bearings, researchers employ advanced tools and methodologies. This study utilized cutting-edge software such as CATIA 5.1, ANSYS 2021R1, and MATLAB R2021a to investigate how the surface characteristics of bush bearings influence their performance under dynamic loads. The research employed both finite element analysis and Artificial Neural Network (ANN) modeling, demonstrating a comprehensive approach to understanding and predicting bush bearing behavior.

The integration of ANSYS results into MATLAB facilitated the development of an ANN model for performance prediction. This innovative methodology allowed for a thorough analysis of total deformation, equivalent stress, equivalent elastic strain, directional deformation, force reaction, and pressure. While full simulations were found to be time-consuming for day-to-day engineering tasks, the study revealed that simplified models could successfully estimate crucial parameters, offering a practical solution for engineers in their design and analysis endeavors.

In the following sections, we delve into the intricacies of meshing and the collaborative use of CATIA, ANSYS, and MATLAB to gain valuable insights into the dynamic behavior of bush bearings. This multidimensional approach not only advances our understanding of these critical components but also contributes to the ongoing optimization of rotating machinery in industrial settings.