Finite Element Method and Artificial Neural Network-Based Parametric Study on Multi-Cylinder Engine Crankshaft Analysis

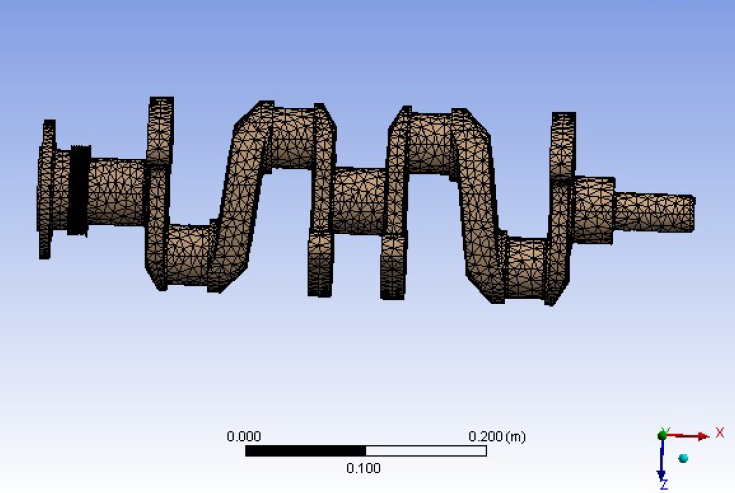

The crankshaft, a cornerstone in the realm of internal combustion engines, assumes a critical role as it withstands formidable loads, enduring cycles of intense bending and torsion stresses. This study delves into an exhaustive parametric analysis of the Multi-Cylinder Engine Crankshaft, aiming to unravel the intricacies of its performance characteristics under varying conditions. By leveraging a sophisticated 3D model of the crankshaft, the analysis strategically incorporates symmetry wherever possible, streamlining the exploration of governing parameters such as journal diameters, journal overlap, crankpin dimensions, and web thickness.

At the core of this research lies the paramount objective of meticulously scrutinizing the performance nuances of the Multi-Cylinder Engine Crankshaft. This endeavor adopts an integrated approach, harnessing the synergies of CATIA, ANSYS, and MATLAB to delve into the intricacies of the crankshaft’s behavior. This multidimensional methodology, encompassing finite element analysis (FEA) and artificial neural network (ANN) analyses, provides a holistic understanding of the crankshaft’s dynamic response under diverse operational scenarios.

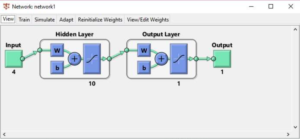

Throughout this study, ANSYS-generated results serve as pivotal inputs for MATLAB, facilitating the development of an intricate artificial neural network model tailored for performance prediction. The integration of these cutting-edge computational tools unveils a comprehensive insight into the crankshaft’s response, allowing for a predictive understanding of its behavior. While a full-scale simulation of the crankshaft process emerges as prohibitively time-consuming for routine engineering applications, the study establishes that critical parameters such as Total Deformation, Equivalent Stress, Equivalent Elastic Strain, and Strain Energy can be accurately forecasted with simplified models.

The seamless integration of CATIA, ANSYS, and MATLAB not only augments the efficiency of the analysis but also provides a nuanced comprehension of the complex interplay between various parameters influencing crankshaft performance. The synergy of these advanced software tools catalyzes an in-depth exploration, unraveling the multifaceted dynamics of the crankshaft’s response to varying conditions.

In essence, this comprehensive investigation transcends traditional analyses, offering a pioneering approach to Multi-Cylinder Engine Crankshaft design and performance prediction methodologies. The study’s findings underscore the significance of embracing a multidisciplinary approach, harmonizing advanced computational techniques and empirical insights to address the intricate challenges associated with critical engine components. By pushing the boundaries of conventional methodologies, this research contributes to the optimization of Multi-Cylinder Engine Crankshaft design, advancing the frontiers of engineering excellence.