Parametric Finite Element Simulation Analysis of the Copper Alloy Rolling Process

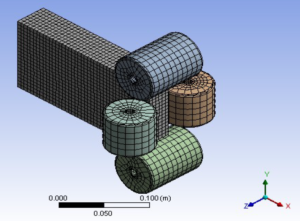

A sophisticated finite element model has been meticulously crafted to simulate the intricate rolling processes inherent to nonlinear Copper alloy behavior. This model is specifically tailored for I-section flat rolling stock characterized by a rectangular cross-section, providing a comprehensive analytical tool for studying the flat rolling of Copper alloy rectangular strips across diverse parameter configurations. It equips rolling designers with insights into the intricate behavior of Copper alloy throughout various rolling passes.

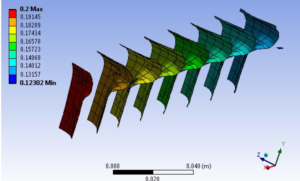

The developed models incorporate a holistic consideration of non-linearities intrinsic to the rolling problem, encompassing material, geometric, boundary, and heat transfer aspects. Employing a coupled thermal-mechanical analysis approach enables a nuanced examination of the interplay between mechanical and thermal phenomena. The model yields predictions for essential parameters such as equivalent stress, equivalent elastic strain, total deformation, total thickness % reduction, and equivalent stress for rollers during the rolling processes. The results obtained through the finite element (FE) model surpass those derived from classical rolling theory, underscoring the model’s enhanced predictive capabilities.

Furthermore, the model highlights the pivotal role played by contact-induced frictional stresses in the rolling process. The analysis underscores the precision achieved in modeling Copper alloy behavior during rolling, employing the elastic-plastic formulation with a von Mises yield surface. Additionally, the FE models reveal the applicability of the rigid-visco plastic formulation for Copper alloy during high-temperature rolling, where flow stresses are contingent upon both strain and temperature.

In essence, this comprehensive analysis not only advances the understanding of Copper alloy behavior in rolling but also emphasizes the significance of employing advanced modeling techniques, particularly within the realm of finite element simulations, to capture the intricacies of metal deformation processes.