Integrated Evaluation of Aluminium Alloy Sheet Metal Forming: A Comprehensive Study Employing Finite Element Method and Regression Analysis

In the dynamic landscape of modern manufacturing, the exigency for production technology flexibility has become increasingly pronounced. Traditional forming processes, characterized by intricate and specialized tooling, incur both time and cost-intensive endeavors in design and production. To address these challenges, a recent innovation has emerged in the form of the incremental sheet forming process. This method, rooted in the principles of layered manufacturing, introduces a departure from conventional approaches by employing numerically controlled tool paths that progressively deform the sheet incrementally, section by section.

Unlike traditional methods that rely on pre-formed tooling, incremental sheet forming presents a paradigm shift where the tool dynamically moves along a controlled path, deforming the sheet locally to shape the final product. Notably, two fundamental approaches exist within this innovative technique: forming with support and forming without support.

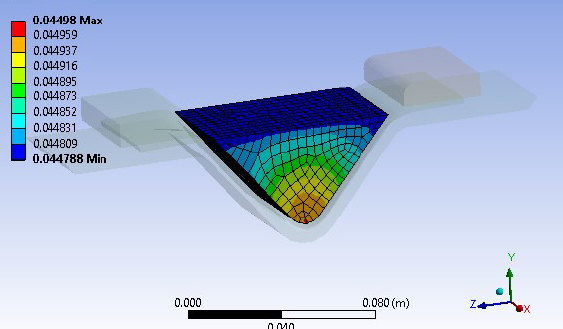

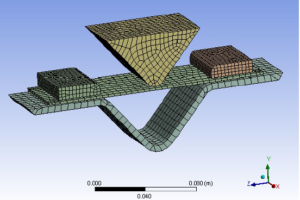

This research embarks on an in-depth exploration of the incremental sheet metal forming process, aiming to discern its intricacies and assess its performance. The overarching goal is to comprehensively study the nuances of this novel process by leveraging advanced software tools such as CATIA, ANSYS, and MINITAB. The multidimensional approach integrates finite element analysis (FEA) and regression analysis, providing a holistic understanding of the incremental sheet metal forming process.

The integration of CATIA and ANSYS facilitates a meticulous examination of the process through finite element analysis, unraveling the complex interactions between various parameters. This analytical depth, however, comes with a trade-off – the computational demands of simulating the entire forming process prove to be prohibitively time-consuming for routine engineering applications. Nevertheless, the study reveals a promising avenue in the realm of simplified models, demonstrating their efficacy in predicting critical factors such as forming forces.

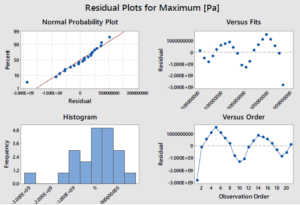

One of the standout features of this research lies in the application of MINITAB for regression analysis, which employs the results from ANSYS to derive a regression equation. This equation becomes a valuable tool for forecasting the performance of the incremental sheet metal forming process. By delving into the intricacies of forming forces and their correlation with various factors, the study provides a nuanced understanding of the process’s predictive capabilities.

In conclusion, this comprehensive exploration transcends the boundaries of traditional sheet metal forming processes, introducing a paradigm shift with incremental sheet forming. The study not only sheds light on the intricate dynamics of this innovative technique but also underscores the significance of advanced computational methodologies in the manufacturing landscape. As manufacturing industries pivot towards more flexible and efficient technologies, the incremental sheet forming process emerges as a noteworthy contender, offering a pathway to streamlined production with reduced tooling complexities.